FEA (Finite Element Analysis)

Finite Element Analysis (FEA) is the use of computer software to simulate performance in order to improve product designs or assist in the resolution of engineering problems for a wide range of industries. This includes Simulation, Validation, and Optimization.

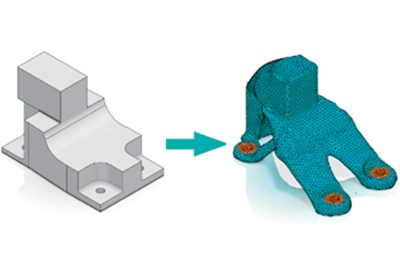

A typical FEA process comprises of pre-processing, solving, and post-processing steps. In the pre-processing phase, engineers model the geometry (or a system representation) and the physical properties of the design, as well as the environment in the form of applied loads or constraints. Next, the model is solved using an appropriate mathematical formulation of the underlying physics. In the post-processing phase, the results are presented to the engineer for review.

The benefits of FEA include reduced product development cost and time, with improved product quality and durability.

ERFOLGutilizes their years of experience from a wide range of projects for Automotive, Aerospace, Oil & Gas, Heavy Engineering and Solar Industries.

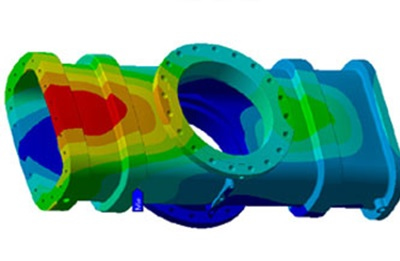

Structural simulation is used to calculate stresses generated in solid structures, for optimization & for selection of suitable material. Typical applications in Automotive, Aerospace, Oil & Gas, Heavy Engineering and Solar Industries. All structures need to have appropriate stiffness & strength. It describes the load resisting properties of the specified material and prevents a structure from stretching, thinning, bending or distorting to a non-permissible extent while in use. The stiffness itself depends on the structure's material and geometry. ERFOLG Engineers study the stiffness of structures and analyze what geometry would produce optimum stiffness for a specific product and define what types of stiffness are suitable and beneficial for the product in question.

Structural simulation is used to calculate stresses generated in solid structures, for optimization & for selection of suitable material. Typical applications in Automotive, Aerospace, Oil & Gas, Heavy Engineering and Solar Industries. All structures need to have appropriate stiffness & strength. It describes the load resisting properties of the specified material and prevents a structure from stretching, thinning, bending or distorting to a non-permissible extent while in use. The stiffness itself depends on the structure's material and geometry. ERFOLG Engineers study the stiffness of structures and analyze what geometry would produce optimum stiffness for a specific product and define what types of stiffness are suitable and beneficial for the product in question.

When designing high performance components, simulating true material behavior, or modeling contacts, nonlinear analysis is a must. Dynamic analysis allows for the time-dependent calculation of displacements, stresses, and strains in one or more solid bodies subjected to loading. Inertial effects are taken into account and the simulation proceeds in real time steps. ERFOLG has many years of extensive experience in structure simulation.

When designing high performance components, simulating true material behavior, or modeling contacts, nonlinear analysis is a must. Dynamic analysis allows for the time-dependent calculation of displacements, stresses, and strains in one or more solid bodies subjected to loading. Inertial effects are taken into account and the simulation proceeds in real time steps. ERFOLG has many years of extensive experience in structure simulation.

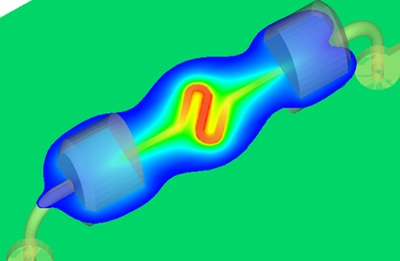

Thermal-Electric interaction (also known as Joule heating) allows coupled simulation between electrical current flow and local resistive heating. Current flow generates heating, heating changes resistivity, resistivity change alters current flow. This type of simulation is useful in sensitive electronics devices such as fuses, links, electrical traces, and lightbulb filaments.

Thermal-Electric interaction (also known as Joule heating) allows coupled simulation between electrical current flow and local resistive heating. Current flow generates heating, heating changes resistivity, resistivity change alters current flow. This type of simulation is useful in sensitive electronics devices such as fuses, links, electrical traces, and lightbulb filaments.

The Thermal-Electric Metaphysics capability to provides a complete fully-coupled capability including nonlinear effects in material properties in both the electrical and thermal physics components. This allows a full range of Joule heating capabilities to be simulated within the familiar environment.

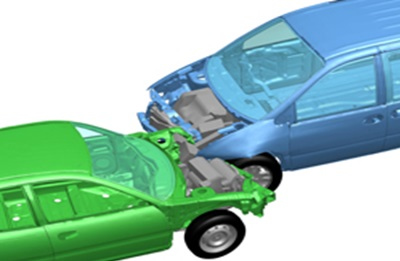

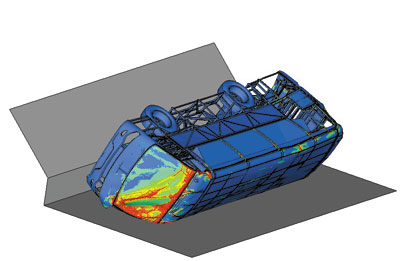

Crash simulations are used wherever developers wish to study and optimize the behavior of structures in a collision. Areas of use include the aerospace, automotive, Oil & Gas and Heavy Engineering. ERFOLG is able to provide virtual simulation of required tests and scenarios in all fields, thus ensuring that the requirements of legislators, consumer protection associations and manufacturers are met. ERFOLG calculates, analyses and simulates the energies and structure deformations produced by a crash and their effects. The specific FE analysis used is able to map non-linearity with regard to material and material behavior, large deformations, contacts and other factors in a realistic way.

Crash simulations are used wherever developers wish to study and optimize the behavior of structures in a collision. Areas of use include the aerospace, automotive, Oil & Gas and Heavy Engineering. ERFOLG is able to provide virtual simulation of required tests and scenarios in all fields, thus ensuring that the requirements of legislators, consumer protection associations and manufacturers are met. ERFOLG calculates, analyses and simulates the energies and structure deformations produced by a crash and their effects. The specific FE analysis used is able to map non-linearity with regard to material and material behavior, large deformations, contacts and other factors in a realistic way.

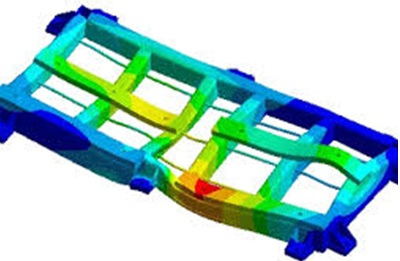

Bus rollover is one of the most serious types of accident as compared to other modes of bus accidents. Strengthening bus frame maintain residual space (occupant space) and minimizing occupant injury are necessary. We are particularly focuses on product development with special attention paid to technical advisory services with regard to characteristics and their optimization.

ERFOLG has also successfully executed the FE modelling of the complete Bus model and carried out the Bus Roll over analysis.

Bus rollover is one of the most serious types of accident as compared to other modes of bus accidents. Strengthening bus frame maintain residual space (occupant space) and minimizing occupant injury are necessary. We are particularly focuses on product development with special attention paid to technical advisory services with regard to characteristics and their optimization.

ERFOLG has also successfully executed the FE modelling of the complete Bus model and carried out the Bus Roll over analysis.

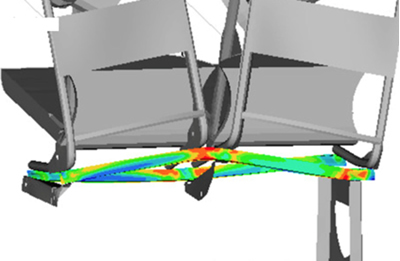

One of the most challenging tasks of development process is prediction of failure over time. Without knowledge of how a structure might fail, it’s tough to improve its safety performance. ERFOLG has an expertise in durability analysis from FEA is becoming increasingly accepted in the design process. The analysis is no longer limited to fatigue life calculations output can now include safe working stresses, warranty claim curves, and the effects of high temperatures, manufacturing processes and assembly stresses.

One of the most challenging tasks of development process is prediction of failure over time. Without knowledge of how a structure might fail, it’s tough to improve its safety performance. ERFOLG has an expertise in durability analysis from FEA is becoming increasingly accepted in the design process. The analysis is no longer limited to fatigue life calculations output can now include safe working stresses, warranty claim curves, and the effects of high temperatures, manufacturing processes and assembly stresses. Wecalculates potential optimization for a design using different numerical processes. Once potential is identified, recommendations for improvements to a component or an assembly group are integrated into the development process. A proposal for a completely new design is also possible. Our engineers work in close agreement with all departments during all stages of the development process. The component design concept is taken into account alongside material requirements, functionality or boundary conditions in the production process.

Wecalculates potential optimization for a design using different numerical processes. Once potential is identified, recommendations for improvements to a component or an assembly group are integrated into the development process. A proposal for a completely new design is also possible. Our engineers work in close agreement with all departments during all stages of the development process. The component design concept is taken into account alongside material requirements, functionality or boundary conditions in the production process.

The approach to CAE optimization varies according to requirements. The type of process chosen depends on the desired improvement: